Your Trusted Partner for Roofing Solutions

Scroll down

Scroll down

Scroll down

About BEMO International

The Sky's The Limit

BEMO International is a Singapore-based designer and manufacturer of advanced standing seam roof systems. Our solutions are engineered for flexibility, durability, and architectural expression—supporting complex building geometries while delivering long-term performance. Backed by our parent company, Yan San Metals Pte Ltd, we help turn ambitious architectural visions into reality.

Our Certifications

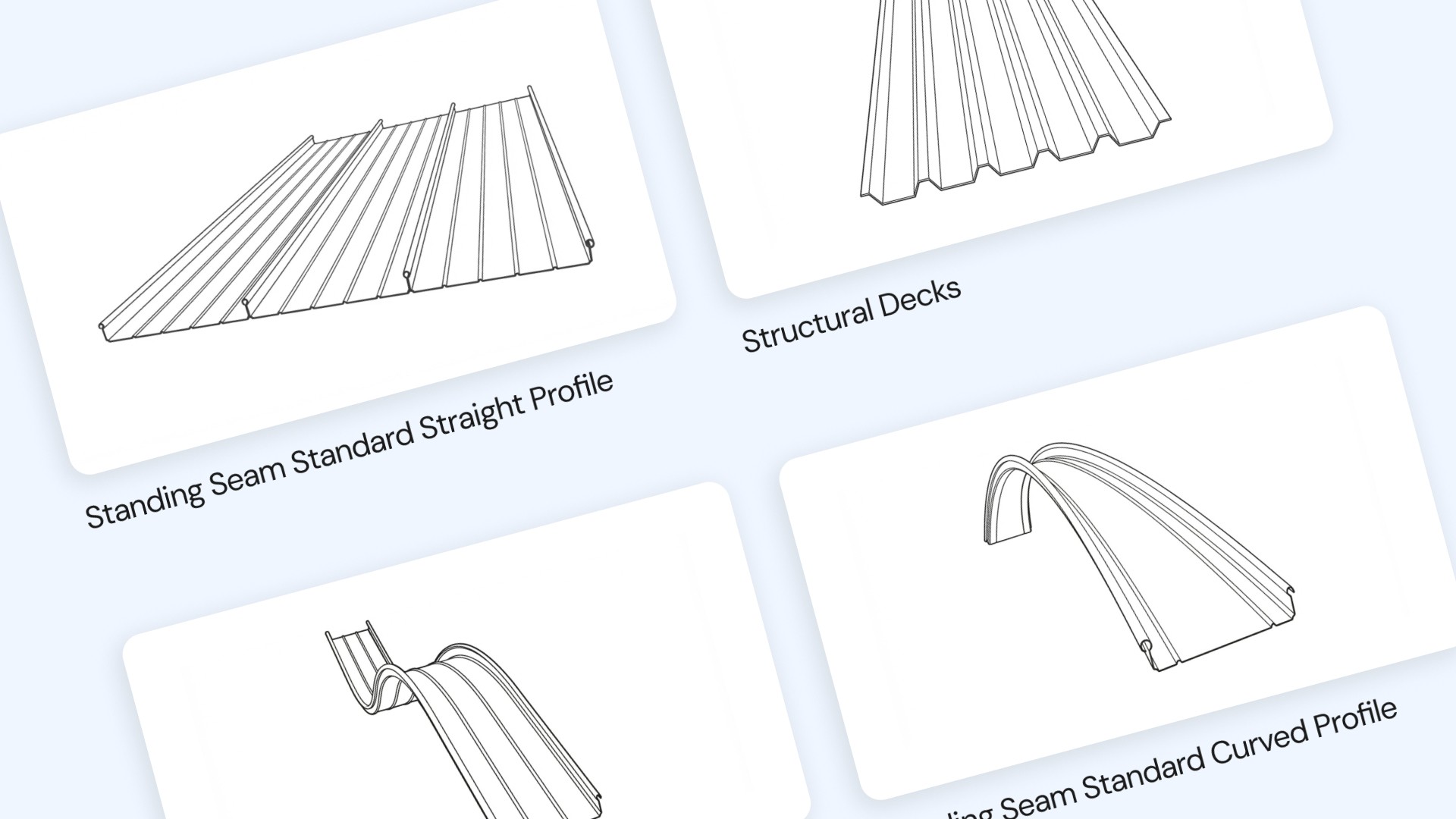

BEMO Product Solutions

Discover our product range and

find your ideal system solution

BEMO Product Solutions

Discover our product range and

find your ideal system solution

BEMO Product Solutions

Discover our product range and

find your ideal system solution

Featured Projects

We've implemented visionary ideas and delivered solutions that meet the highest quality standards

Featured Projects

We've implemented visionary ideas and delivered solutions that meet the highest quality standards

Featured Projects

We've implemented visionary ideas and delivered solutions that meet the highest quality standards

Tuas Depot, Singapore

Our Approach

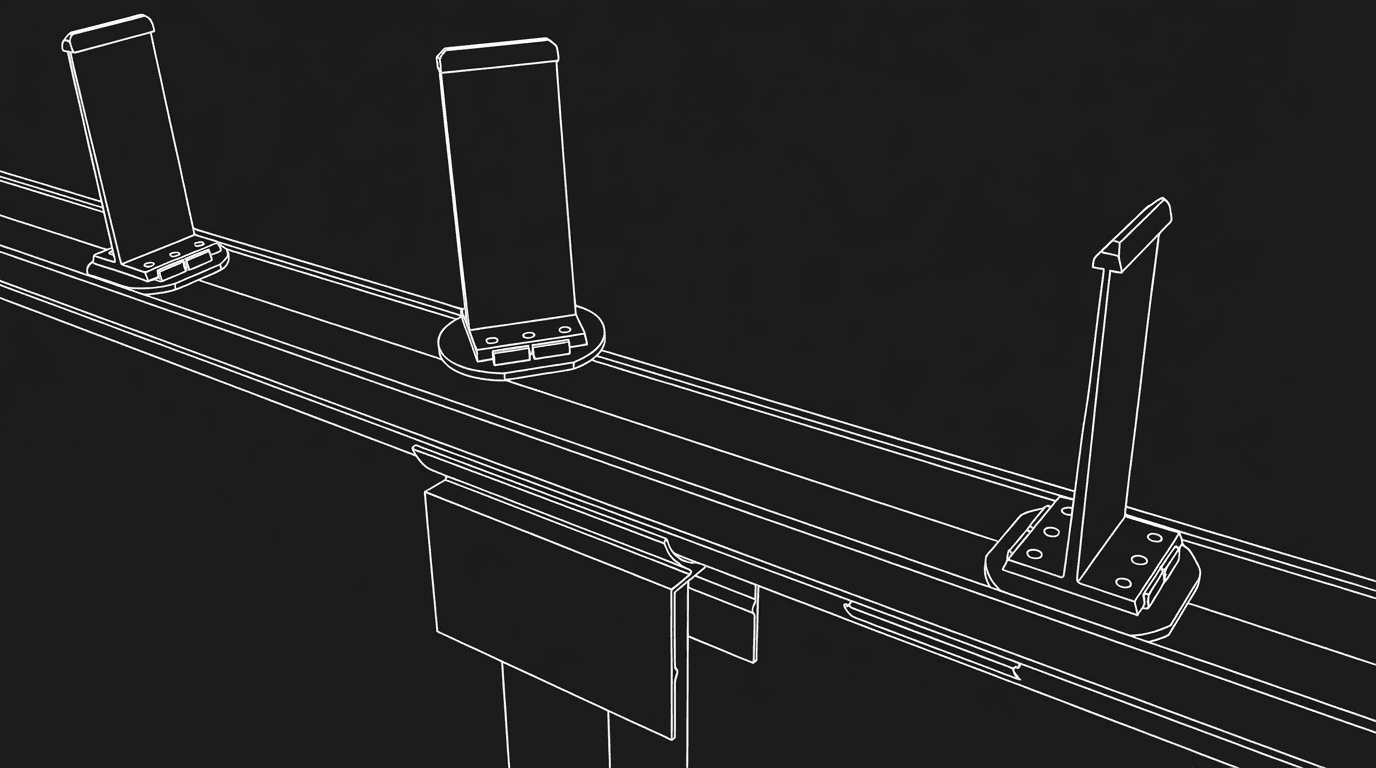

The Tuas Depot project showcases an innovative long-length roofing system produced through advanced Ramp-Up Roll Form and Sky Roll Form techniques. By combining ground-level ramp forming with elevated roll forming, roofing panels are seamlessly shaped and installed in continuous lengths, eliminating the need for joints. The system features the Aluminium Standing Seam 65/400 profile, supported by Top Hats, Halters, and Insulpak thermal layers integrated with Insulation Wool Block. Designed for superior durability, weather resistance, and thermal performance, this solution offers a sleek, modern finish ideal for large-span roof structures.

Featured Products/ Methods Used:

Ramp-Up Roll Form

Sky Roll Form

Long Length Roof without Joints

Aluminium Standing Seam (65/400)

Top Hat, Halters, Insulpak, Insulation Wool Block

Tuas Depot, Singapore

Our Approach

The Tuas Depot project showcases an innovative long-length roofing system produced through advanced Ramp-Up Roll Form and Sky Roll Form techniques. By combining ground-level ramp forming with elevated roll forming, roofing panels are seamlessly shaped and installed in continuous lengths, eliminating the need for joints. The system features the Aluminium Standing Seam 65/400 profile, supported by Top Hats, Halters, and Insulpak thermal layers integrated with Insulation Wool Block. Designed for superior durability, weather resistance, and thermal performance, this solution offers a sleek, modern finish ideal for large-span roof structures.

Featured Products/ Methods Used:

Ramp-Up Roll Form

Sky Roll Form

Long Length Roof without Joints

Aluminium Standing Seam (65/400)

Top Hat, Halters, Insulpak, Insulation Wool Block

Tuas Depot, Singapore

Our Approach

The Tuas Depot project showcases an innovative long-length roofing system produced through advanced Ramp-Up Roll Form and Sky Roll Form techniques. By combining ground-level ramp forming with elevated roll forming, roofing panels are seamlessly shaped and installed in continuous lengths, eliminating the need for joints. The system features the Aluminium Standing Seam 65/400 profile, supported by Top Hats, Halters, and Insulpak thermal layers integrated with Insulation Wool Block. Designed for superior durability, weather resistance, and thermal performance, this solution offers a sleek, modern finish ideal for large-span roof structures.

Featured Products/ Methods Used:

Ramp-Up Roll Form

Sky Roll Form

Long Length Roof without Joints

Aluminium Standing Seam (65/400)

Top Hat, Halters, Insulpak, Insulation Wool Block

NTUC Warehouse, Singapore

Our Approach

The NTUC Warehouse project features a state-of-the-art, long-length roofing system designed for superior durability and efficiency. Using on-ground roll forming combined with a precision lifting beam system, the roofing panels were produced and hoisted directly into position, ensuring a seamless installation with no joints. The design incorporates the Aluminium Standing Seam 65/400 profile, supported by Top Hats, Halters, and Insulpak with Insulation Wool Block to deliver enhanced thermal performance and weather protection. This project highlights our expertise in delivering large-scale, joint-free roofing solutions with exceptional precision, craftsmanship, and finish.

Featured Products/ Methods Used:

Aluminium Standing Seam (65/400)

Long Length Roof without Joints

Lifting Beam Method

Top Hat, Halters, Insulpak, Insulation Wool Block

NTUC Warehouse, Singapore

Our Approach

The NTUC Warehouse project features a state-of-the-art, long-length roofing system designed for superior durability and efficiency. Using on-ground roll forming combined with a precision lifting beam system, the roofing panels were produced and hoisted directly into position, ensuring a seamless installation with no joints. The design incorporates the Aluminium Standing Seam 65/400 profile, supported by Top Hats, Halters, and Insulpak with Insulation Wool Block to deliver enhanced thermal performance and weather protection. This project highlights our expertise in delivering large-scale, joint-free roofing solutions with exceptional precision, craftsmanship, and finish.

Featured Products/ Methods Used:

Aluminium Standing Seam (65/400)

Long Length Roof without Joints

Lifting Beam Method

Top Hat, Halters, Insulpak, Insulation Wool Block

NTUC Warehouse, Singapore

Our Approach

The NTUC Warehouse project features a state-of-the-art, long-length roofing system designed for superior durability and efficiency. Using on-ground roll forming combined with a precision lifting beam system, the roofing panels were produced and hoisted directly into position, ensuring a seamless installation with no joints. The design incorporates the Aluminium Standing Seam 65/400 profile, supported by Top Hats, Halters, and Insulpak with Insulation Wool Block to deliver enhanced thermal performance and weather protection. This project highlights our expertise in delivering large-scale, joint-free roofing solutions with exceptional precision, craftsmanship, and finish.

Featured Products/ Methods Used:

Aluminium Standing Seam (65/400)

Long Length Roof without Joints

Lifting Beam Method

Top Hat, Halters, Insulpak, Insulation Wool Block

Changi Airport Terminal 4, Singapore

Our Approach

The Changi Airport Terminal 4 project features a premium roofing system engineered with the Aluminium Standing Seam 65/400 and Structure Deck 85/280 profiles. Designed to meet high-performance standards, the system integrates Top Hats, Halters, and Insulpak with Insulation Wool Block to provide superior thermal efficiency, structural strength, and weather resistance. This installation exemplifies our commitment to precision, durability, and architectural excellence in large-scale commercial roofing applications.

Featured Products/ Methods Used:

Aluminium Standing Seam (65/400)

Structure Deck (85/280)

Top Hat, Halters, Insulpak, Insulation Wool Block

Changi Airport Terminal 4, Singapore

Our Approach

The Changi Airport Terminal 4 project features a premium roofing system engineered with the Aluminium Standing Seam 65/400 and Structure Deck 85/280 profiles. Designed to meet high-performance standards, the system integrates Top Hats, Halters, and Insulpak with Insulation Wool Block to provide superior thermal efficiency, structural strength, and weather resistance. This installation exemplifies our commitment to precision, durability, and architectural excellence in large-scale commercial roofing applications.

Featured Products/ Methods Used:

Aluminium Standing Seam (65/400)

Structure Deck (85/280)

Top Hat, Halters, Insulpak, Insulation Wool Block

Changi Airport Terminal 4, Singapore

Our Approach

The Changi Airport Terminal 4 project features a premium roofing system engineered with the Aluminium Standing Seam 65/400 and Structure Deck 85/280 profiles. Designed to meet high-performance standards, the system integrates Top Hats, Halters, and Insulpak with Insulation Wool Block to provide superior thermal efficiency, structural strength, and weather resistance. This installation exemplifies our commitment to precision, durability, and architectural excellence in large-scale commercial roofing applications.

Featured Products/ Methods Used:

Aluminium Standing Seam (65/400)

Structure Deck (85/280)

Top Hat, Halters, Insulpak, Insulation Wool Block